Mr. George H. Sackett designed a pretty poor pen. Of course that sounds harsh a 124 years after the fact, but I’ve been examining the results of his fertile imagination and have come to that conclusion. Before discussing this curiosity more let me say I can’t blame him too much since early fountain pens are odd beasts as inventors and companies in the early days tried to morph them from glorified dip pens with a built in ink supplies to dependable instruments which would not alter your finger color. It was a free-for-all at the time since it was easy for someone to take a tube, stick a nib on the end, and engineer what was between based on simple physics and bizarre notions.

I’m not sure if back then people thought building the perfect fountain pen would have the world beating a path to their door but it seems so. Type the word “Fountain Pen” into the Google patent databases and you’ll see enough listings to bug out your eyes. We tend to think the implement we nib fanciers use is a proven mechanical device and focus on aesthetics or usability but these early patents are an indicator how long the development process took. Nozzles, tubes, valves, and other tiny internal workings are intricately drafted in the old records and illustrate the inventor’s genius or insanity. Time and time again great self-assurance shines through in the pages and pages of descriptions and diagrams that are found.

The designer of the pen in question, Mr. Sackett, had at least three patents for a fountain pen (here, here and here) which show seemingly the same construction. Why the individual patents were filed and granted (just months apart in 1886) is confusing. The last tidbit is that an advertisement for this pen listed an 1885 patent but I can’t find it. This muddle aside it does seem there was little time wasted before manufacturing started since ads can be found from 1885. I’m neither a good researcher nor a patent expert so I can offer no explanations for all this. I’ll chalk it up to something unfathomable from the distant past which is another way of me saying I didn’t bother any further with the mystery.

Who was the inventor? Thanks to a family history I did find out a few factual items. His entry read as below:

GEORGE HENRY SACKETT, 1826-, of Providence, R. I., and Brooklyn, N. Y., son of Isaac and Mary Johnson Sackett, was married at Providence, R. I., July 27, 1857, to SARAH SWEETSER SHELDON. He was, from 1855 to 1878, a member of the firm of Sackett, Davis & Co., jewelry manufacturers, of Providence, R. I., and is the inventor of the Sackett fountain pen.

As you can see Mr. Sackett’s eponymous pen was considered an important enough achievement to be listed as one of his two accomplishments.

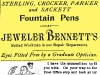

In that biographical tidbit it’s interesting to see that he was jeweler like many people involved in the nascent fountain pen industry. His invention seemingly got him out that business and by 1890 the Sackett Fountain Pen Co was located at 169 & 171 Broadway in New York City – at the corner with Maiden Lane, which was a hub for Jewelers in the city as well as many writing instrument companies as Waterman’s and Mabie, Todd & Co. One of the companies neighboring the location was the William S. Hicks Company which sold fountain pens both under its own name and for such high end establishments as Tiffany’s and Cartier. Many of these were beautiful, expensive pens and pencils made from precious metals and are prized today.

I’ve not found when or why Sackett and Hicks got together to brand and sell the pen designed by the former. Advertisements from the beginning list the pen as the “Hicks-Sackett”. Being an older and more established firm Hicks could have offered manufacturing capabilities and a proven distribution channel which must have been appealing. The elder firm may have wished for a low cost line of pens to market and latched upon this design as the one that fit the bill. Either way the pens were made from around the patent date till at least late into the first decade of the 20th century. By the late oughts the pen was quite a dinosaur since its competitors had invaluable features as modern channeled feeds to regulate ink flow and combs to catch excess ink. Add the use of screw caps and self-filling systems in some marketed pens and – even at a low price – the Hicks-Sackett pen was a doddering holdover from an earlier era.

The following might be dry, boring, and maybe even confusing in describing how this oddball pen works and includes illustrations that may make you squint and get a headache. With that caveat lets look at the pen parts and the basic principles of how they function. The first image below is from the patent that is best represents the actual pen sold. The second scan is a detailed illustration from an advertisement that also backs up that claim.

Externally it’s unremarkable except for probably the first thing you’ll notice: The slip cap has a smaller diameter “crown” on the end. In my opinion this is the cleverest feature of the pen since the protrusion into a hole on the opposite end to allow posting. It’s a nice, tight fit and there’s no chance of a ring around the barrel ever forming from the friction of a cap being placed over it.

Internally what you see illustrates its origins in the late 19th century when fountain pens were in their infancy. As stated earlier the Hicks-Sackett is without the later innovations which made pens reliable and predictable in use and throughout the long period it was manufactured was frozen like this. In a nutshell it is basically a chased thin black hard rubber tube with an odd feed rod inside and flat triangular bit acting as a rudimentary feed.

The most prominent part that extends inside the barrel front to back is the “feeding stem”. This long grooved bar looks like a narrow feed on steroids but the patent text tells you the reason for it is to transmit the last bit of ink clinging to the walls of the pen to the nib via capillary action. That’s a reason but a silly one indeed. As seen in some of the Hicks-Sackett advertisements in the gallery below using the last drops of ink was brag worthy and for some reason the period around the turn of the 19th century was one where pen manufacturers fretted about this ability in their products. If you look at how pens like the Parker “Lucky Curve” touted their ink evacuation ability it seems like this was something the masses were demanding. From the hyperbole of the advertisements violent mobs must have gathered to chant “No ink left behind!” Of course this was just a marketing ploy since everyone wanted their pen to stand out in some way and this was flashier than saying “our cap stays on!” or “the pen that makes lines on paper!” The entire idea seems to have been abandoned as other things could be patented and harped upon like filling methods or interchangeable nibs. History shows people were alright with refilling their pens prior to that last drop being used since later pens phased out the gimmicks that were supposed to throttle the last of the ink out.

So the snake-like “feeding stem” which was inside the pen got a lot of thought. Unluckily nothing much else seems to have, especially the feed. Many contemporary pens had an over and under feed in the Hicks heyday and one could justify how elaborate these were since the super flexible nibs of the time needs a ink to gush down to where the rubber (read nib) met the road (nee paper). The Hicks-Sackett didn’t even bother with the underfeed that is still currently used in fountain pens and instead has a triangular sliver of hard rubber above the nib which has a standoff to make a gap which pulls ink out via capillary action. What is desperately missed is something like feed groves to allow air back up into the reservoir to fill the void ink leaves behind in a metered fashion. Everything happens on this pen through the same tiny slit behind the nib which the patent gobbled gook says will work just awesomely. In reality it allows air and ink enter an exit willy-nilly resulting in the occasional glob of ink coming out when air rushes through too fast. Aesthetically I love the way the nib looks – like a dip pen’s from underneath but that doesn’t compensate for the poor functionality.

My criticisms wouldn’t hold water with the copy writers who created the ads for the pen as profuse praise was heaped upon by them. What kind of drugs they were on as they wrote these I don’t know, but one claim is that you will not get your fingers inky when refilling it. Possibly they had soot blackened fingers (Dickensian image) so they never noticed this pen almost guarantees ink stained digits. There is no section at the front and the barrel just continues jauntily on till it comes to an abrupt end. Here the feed and nib is held in place by a plug that friction fits into the hollow of the inside void. Removing it means you have to grasp the feed and nib between your finger and thumb and you know what liquid is on them? Yes, ink.

None-the-less the ads I dug up for this pen are a fun romp through a time long past. Look at the hyperbole in them for a quick giggle. I’ve found as many as I can so you can see that the pen never altered over its marketing life. If you do see these and wish to go back in time to purchase I recommend you first look at a certain new pen by a Mr. Sheaffer he calls a “lever filler”. I also heard Mr. Waterman makes a fine product too.

What I love the most about researching this pen was finding the original patents and taking in their lovely language. On both you see Mr. Sackett tried to cover as many bases as possible by explaining alternative ways of executing his design. I have to say you can almost buy that this pen will revolutionize the field as the grandiosity of the design is teased out for you. If it only had a tiny steam engine and flapping wings you could see this as a prop in some modern steampunk fiction and called “Dr. Hermes’ Incredible Levitating Ink Fountain Marking Machine”.

The Hicks-Sackett pen is fascinating, odd, frustrating, and wonderful to explore. Some questions remain like why Hicks was associated with this pen and how it continued to be sold when as it become so inferior to its competition. But I’ll not trouble myself with that since I am not a historian but an observer. The pen that is pictured in this post has been passed to its new owner who has used it in part to create the wonderful illustration below. This proves that talent trumps technology – or something like that.